(back to mainpage)

- On the CCB there are

2 connectors for the Led-Alignment link. Which one have to be used?

- On the CCB there are

two different sets (one for type A and one for type B) of connectors for

test pulse cables. Connectors inside the same set are equivalent?

- What can be done if

one test pulse theta cable is broken and no spares are available?

- Where

can be measured (with a multimeter) voltages and threshold applied on the

front-end boards on a chamber?

- What

is the sequence of operations when the Boundary Scan Test performs the check

of Sequence Test and Sequence Reset nets?

- How

to do if , when the check of Sequence Test and Sequence Reset sometimes

fails?

- How

to interpret an error (at the MC boot level) signaled on the TP1H-L or

TP2H-L fields?

- Why

the snap/reset test sometimes performs successfully (e.g. without signal

cables or when the front-end are switched off) and sometimes fails?

- The

MC full test program fails in measuring the voltages on the Splitter Board

or when it tries to set the front-end threshold?

- How

to update the MC full test program when a newer version is up?

- Is

there the following error on the read test result?

Error: some ADC noise are equal to 3 and the error flag is

active, while some other channels are higher (e.g. channel 24 set to 26).

Moreover the voltages read on the Splitter Board are lower than expected

(e.g. Vcc = ~2.7 V , Vdd = ~1.55 , when the expected values are Vcc = ~5.1 V

, Vdd = ~2.8 ), while voltages on the front-end side are corrected (both

from the MC status and the measurement on the front-end test points).

- Has

the clock to all TRBs the same phase?

- The

PN1 switch close to the TRB-PHI clock connector is open (10 kohm) when

measured with a multimeter but the MC full test program recognizes it as

closed?

- Is

VCCin (the voltages applied with the 5V low power supply to the MC) badly

measured in the MC status data?

- Which

voltages must be applied to the Splitter Board power supplies?

- How

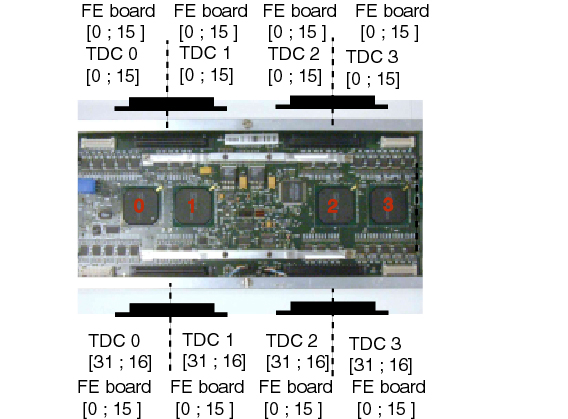

the front-end channels are related to the cell position into a superlayer?

- How

the front-end cables and channels are connected into TDCs channels on ROBs?

- How

the clock signal is distributed inside the MC? Concerning the clock signals

coming to different devices, which phases are fixed in hardware and which

ones can be tuned?

- When

looking at TDC status with the full MC test program, all channels are

correctly enabled (green lights) but the red error led of some TDCs in

on?

- The

ROB power or link cables have been incidentally disconnected, how they have

to be properly inserted?

(top of the

page)

ANSWERS

- Both connectors have pins connected in parallel.

Not using of the connector closer to the RPC-dedicated one is preferred for

optimizing the length and consequently the path of the cable from the CCB to

the Led-Alignment connector at the end of the MC

(top)

- For each set there are 14

connectors placed in two rows. The two connectors in every column are feed

by the same driver and the impedance of each line must be 50

ohm. Only when both connectors in the same column are connected with test

pulse cables correctly inserted to the chamber front-end, the driver works

fine. As information it should be noticed that for the chimney chambers the

number of pairs of theta test pulse cables (of the same type) is odd. Thus,

when MC is installed on the chamber, two

end-plugs (terminating the line with 50 ohm impedance) must be used

(one for type A, the other for type B).

(top)

- Test pulse theta cables are

long 3.5 meters. So, one phi cable of the same length can be used, after

being properly labelled.

(top)

- By looking at one front-end

board in such a way that signal cables (to the MC) should be inserted from

up to bottom, at the right of the connector (sky-blue colored) there are 5

test points. From left to right they are

Vdd (~ 2.5V), Vdd, Fe Width (~ 3V), Vcc(~ 5V),Threshold positive, Threshold

negative. The effective threshold applied to the front-end board is obtained by

measuring the voltage between the Threshold positive and Threshold

negative test point.

(top)

- 1)send to MC the command SelCK =7

(it selects QPLL1 e QPLL2 clock)

2)send the command SelCK=3 (it forces the microcontroller to use the clock

on-board even if QPLL1 and QPLL2 clocks are still active)

N.B.: step 1 and 2 must be done separately otherwise the microcontroller

could reset.

3) read the MC status, for checking that MC is not reset

4) perform a Jtag SAMPLE instruction on TTCrx

5) perform a Jtag Preload/EXTEST instruction on TTCrx in order to put at '0'

logical level the following nets: CKDES1,CKDES2, CK40,

TTCrdy, L1A, L1ACK. All other nets must remain to the logical value read

with the SAMPLE instruction in step 5..

6) repeat step 3.

7) set the broadcast bus to 0x08 (=sequence reset) and

strobe1 to '1', with a EXTEST instruction.

8)check that Sequence Reset read on all ICs on the Board is set to '1'.

9)set the broadcast bus to 0x80 (=sequence test ) ,

strobe2 to '1' and strobe1 to '0' , with a EXTEST instruction.

10)check that Sequence Test read on all ICs on the Board is set to '1'.

11)make a Jtag BYPASS instruction by resetting the TAP controller on TTCrx.

12) send the command SelCK=7 to the MC.

13) send the command SelCK=4 (it selects the clock from the TTC

system)

14) repeat step 3.

(top)

- If the version of the

Boundary Scan Test program is older than 4.3 sometimes can happen that

sequence test or reset are seen to logical level '1' on some ICs.

This happens because the signals are generated into a FPGA in the following

way: when the TTCrx broadcast bus is set to the properly value the signal is

generated for a given duration (about 3 us) then it is reset (for 25-50 ns)

and eventually regenerated. Thus the percentage of

test failure should be 5-10%. It is better to repeat few times the

check and to take as valid result the one which is happened more often.

If the version is newer (or equal ) than 4.3 the check is automatically

repeated up to 10 times. When the first successful occurrence happens the

test ends and, since the connection has been found, the result is positive.

(top)

- The fields TP1H-L and TP2H-L

show the the value TP1H - TP1L and TP2H - TP2L respectively. This difference

must be 1.23V +/- 1-2%. Check the value in the fields and if they are

equal to 1.23V (with a 1-2% tolerance), neglect the errror.

(top)

- When the MC is configured not

all BTIs are configured. This happens because the configuration is optimized

for data taking while, during the test of MC, BTIs are configured when

needed by the several checks. This test needs to have all BTIs configured,

thus it better to do it at last. After this test all BTIs must be

reconfigured.

(top)

- The test program fails in

measuring the voltages on the Splitter Board or when it tries to set the

front-end threshold? Check the threshold cable is completely inserted

specially on the CCB side. Sometimes this can be accidentally disconnected

when the Server Board is inserted. Check also that the threshold cable is

properly crimped.

(top)

- 1) download the updated file (Franco

Gonella communicates where it is)

2) backup the folder \test_mc where the old program is in.

3) delete everything in \test_mc except two following folders:

test data

test bsr

3) unzip the new downloaded file into a temporary folder and then copy all

files and folders into \test_mc

4) when start program for the first time, after typing the MC type

and ID, go to the setup panel, write the server IP address (the port is

18889) and save this information in the file config_def.cfg

(top)

- If ADC noise is lower than 3

it means that threshold cable is correctly connect and the Splitter Board is

switched on. If the noise is greater for a give channel, it means that

channel is floating. For example the channel 24 corresponds to the Vdd

Splitter Board. Check if threshold cable is connected or badly crimped.

(top)

- The clock of all TRB phi has

the same phase. The clock to the TRB theta is delayed in order to compensate

the different length of the phi and theta signal cables from the front-end.

The test which verifies that the clock cables length is correct is the

"BTI skew".

(top)

- When the switch is open the

net connected to the TRACOs has pulled-up to Vcc via a resistor, so that a

logical high level should be set. On some oldest TRBs the resistor has a 10

kohm value. This way a spurious voltages level is obtained (about 2V), so

that the logic level is undefined and the test can fail. The correct

solution is obtained by replacing the resistor (named R15 and placed

between Traco 3 e il Traco 2) with one having 330 ohm value.

(top)

- First of all, check the

voltages on the power supplies side (is a current limiter on? if yes, is it

properly set?). Then check voltages on the low power patch panel. Typical

values are from 0.8V to 1V higher that the nominal ones (e.g.

6V for the 5V and 4.2V for the 3.3V). Check that the other voltages read by

the MC are correct. If all voltages applied are correct the problem could be

in the CCB. In the backside PCB side respect to power connector there are

two resistors (R122 and R123) of 4.7 kohm resistance. Check this value (with

a multimeter) and if they are correctly soldered. If yes, it could be the

case of changing the CCB.

(top)

- The Splitter Board is

connected to the power with 4 cables:

Red : +2.6 V

Brown : return channel of +2.6 V (eventually connected to GND)

Blue : return channel of +5.1 V eventually connected to GND)

Grey : +5.1 V

This values are referred to the nominal and expected ones on the Splitter

Board. Voltages applied on the power supplies could be higher (due to the

voltage fall on cables). Values on the Splitter Board can be checked with a

status command send to the MC connected.

(top)

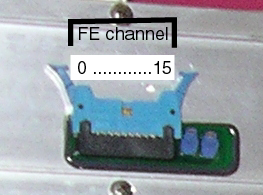

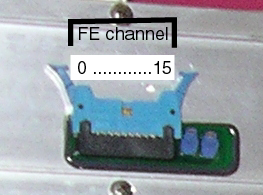

- Each front-end board (1

connector) has 16 signal channels. They are labeled in the following way.

Each front-end board is connected to 16 cells within the same superlayer.

The correspondace between channels and cells is showed in the following

picture

Successive front-end board are connected to successive groups of 16 cells.

(top)

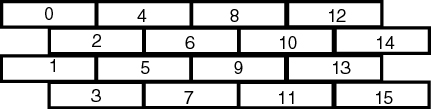

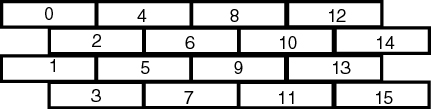

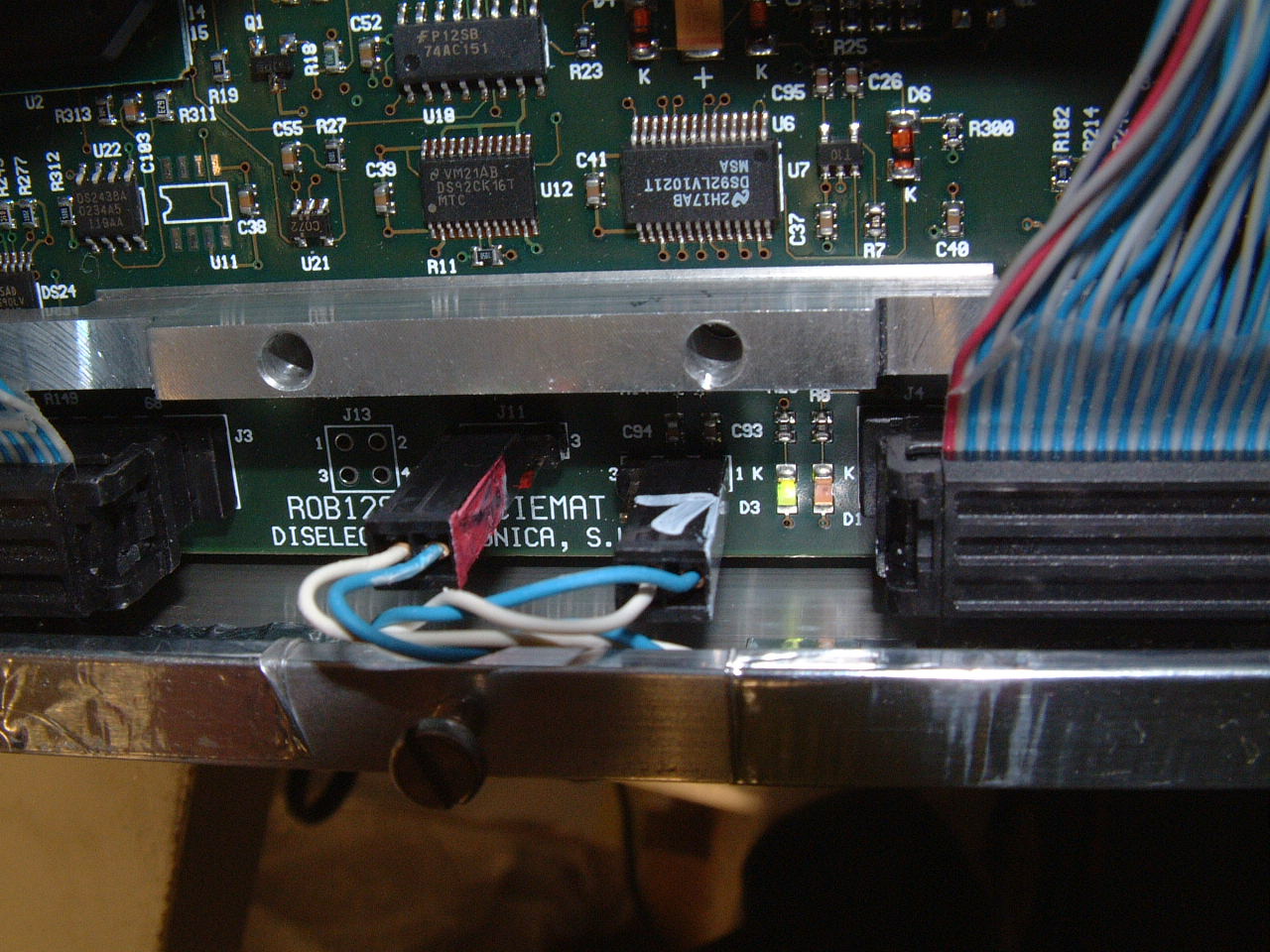

- The following picture shows a ROB how it is seen

when inserted into a MC placed into a DT chamber, keeping PHI1 superlayer at

the bottom and PHI2 at the top.

This way the bottom 2 connectors are used for signal cables from PHI1 while

the upper 2 for cables from PHI2. Each ROB connector is connected to 2

front-end board, one half connector for every front-end board. Mapping

between front-end and TDC channels is shown.

(top)

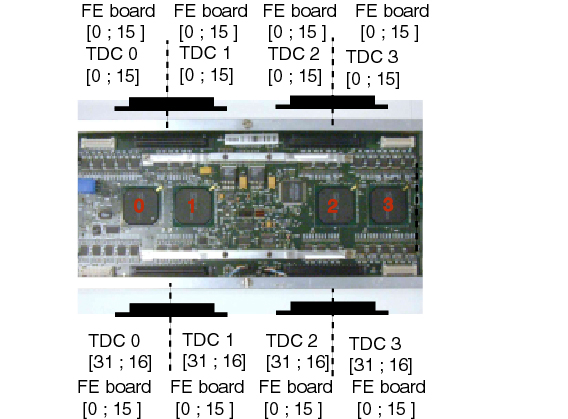

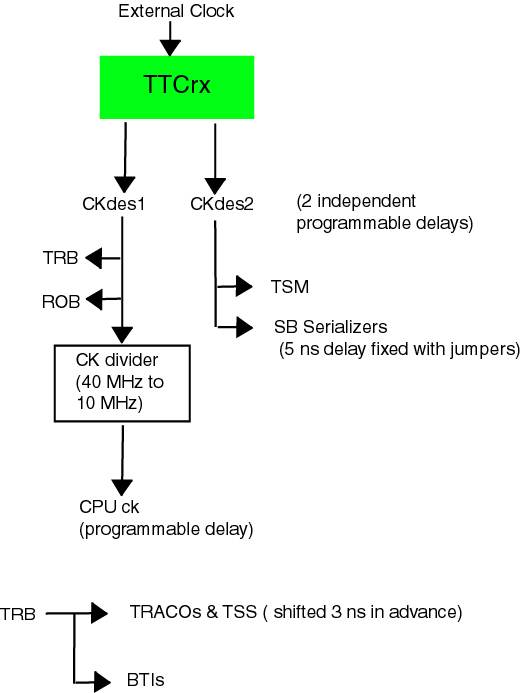

- Diagram below shows the clock distribution inside

the MC

.

The clock signal is sent by the TTC system and received with the TTCrx IC,

hosted on the CCB inside the MC. The TTCrx has 2 clock outputs, called

CKdeskewed1 and CKdeskewed2, whose phases can be independently

delayed. The delay is set by sending the command TTC_FineDelay, whose

parameters are the channel (0 means CKdeskewed1, 1 means CKdeskewed2) and

the delay expressed in ns units. The channel CKdeskewd1 feeds the TRBs and

the ROBs. Moreover, after a frequency divisor (from 40 MHz to 10 MHz), it is

called CPUck and it is trasmitted to the Microcotroller on the SB. The CPUck

phase can be modified with an independent delay. The channel CKdeskewed2

feeds the TSM system placed on the Server Board and the LVDS serializers

which send trigger data to the Sector Collector. The phase difference

between the clock to the TSM and the serializers is fixed in hardware. The

clock into a TRB is divided in 2 lines, one for TRACOs and TSS and the other

for BTIs. The phase difference between these two lines is fixed in hardware.

Thus, only 3 independent clock lines remain: CKdeskewed1, CKdeskewed2 and

CPUck. The line CKdeskewed1 must be delayed by 4 ns. This way

the clock line which feeds TRACOs and TSS is expected to be nearly in phase

with the TSM clock, as foreseen by design for the trigger data transmission

from TRBs to SB. Due to this fact the test_serializers (implemented in the

full MC test) is performed for checking that with 0 ns delay on the

CKdeskewed2 line the trigger data transmission perfectly works. One only

free phase remains to be fixed, the CPUck. Its phase must be adjusted with

respect both to the ROB clock (see MC-RO draft user manual in the CIEMAT web

site, section 3.2.11, where interference between Jtag clock, generated by

the microcontroller and thus dependent on the CPUck, and ROB clock) and the

TRB clock, since it is used for testing trigger path emulating tracks. This

last phase is obtained with the CPUck_phase test in the full MC test

program.

(top)

- Click on the red led and look at the messages in

the bottom of the window. Check if one of these messages appears: "jtag

instruction error" or "setup or control parity error". If so,

the default value of CPUck delay is not correct for this MC, with respect to

the ROB clock (see f.a.q. 18 and MC-RO user manual n the CIEMAT web

site, section 3.2.11). In order to find a correct value, the TDC_Jtag_test

has to be performed. This test, for any TDC, loops by increasing the delay

on the CPUck line and, at each loop, it writes and reads TDC configuration,

searching for errors.. This way a range of values can be found, where CPUck

and ROB clock don't interfere. Then the TDC must be reconfigured and in the

field "CPU ck" in the Configuration panel, a correct value into

the range previously found must be put.

(top)

- Look at the following pic:

These instructions have been taken from a mail sent by Cristina (thanks!):

"the ROB clock cable is connected to the J11

connector in pins 1 and 2 and ROLINK cable to J12 pins 1 and 2. In principle

a "L" is put to the ROLINK cable to avoid confusion, and in

principle, the right side of the ROLINK connector is marked in

white and the right side the rob clock connector

in red (the blue cable should be to the right (pin 2 in ROB ck and pin1

in ROLINK))."

(top)